Installation FAQ

Use the tips below to ensure that your AV installations are safe and successful.

1. When drilling into concrete block, what type of drill should be used?

Always use a standard type electric drill rather than a hammer drill. This will prevent the inside of the block from breaking out when entering the cavity.

2. Is it important to drill into the center of a stud or joist?

Yes, drilling off-center may compromise the holding ability of the fastener.

3. What is the most accurate method of locating utilities such as electric, gas or water lines inside a wall?

Always use an electronic conduit sensor, as built drawings or blueprints will only show the approximate locations of utilities.

4. What types of ceiling mount accessories are available?

Peerless-AV has a ceiling mount attachment for most every type of ceiling structure, including finished ceilings, truss mounts, I-beam mounts, internal joist mounts, Unistrut mounts, cathedral ceiling mounts, suspended ceiling mounts. We also have attachments with anti-vibration stress decouplers.

5. Can the "do-it-yourselfer" install a Peerless-AV mount properly and safely?

Yes, absolutely. All you need are the proper tools and a little common sense. Read through and follow the enclosed detailed instructions. If, for any reason, you are not sure of the mounting surface load capabilities, consult with a certified contractor or architect before continuing.

6. Can steel stud construction carry the same load wood stud can?

No, steel studs can be much weaker than wood depending on their thickness or gauge. Typically, you will find #25 gauge (.020) in most construction, which is totally incapable of safely supporting a 125 pound with a safety factor of four. You then need to spread the load across 2 or 3 studs using a Peerless-AV wall plate designed for that purpose.

- Screw pullout

- Wrong hardware used

- Non-structural wall

- Mount “rigging"

- Product abuse

- “Kid” hanging on the mount

- <1%* mount defect

*Percentage used for relative illustration purposes only.

Togglers acceptable for lighter installations, flat and tilt mounts.

Wall plates may be required for heavier installations, pivot and articulating wall mounts.

Wood stud blocking recommended in some installations.

Follow mount manufacturers' recommendations.

Tough exterior (case), flexible core prevents snapping.

- Metal stud

- 25 gauge (0.018") minimum

- 20 gauge (0.035") or thicker studs recommended

- Use metal stud togglers or wall plate for anchorage

Wood Stud Construction

- 2 x 4 minimum (not 4 x 2)

- Use standard wood screw to install

- Recommend using case-hardened screw

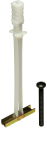

Hardware for Concrete

- 2000 psi minimum concrete

- Use anchor or concrete expansion

- A tight, clean drilled hole is mandatory to avoid pullout

- Fasten using slow setting on drill or use screwdriver

- Cinder block

- 1-3/8” minimum web structural cinder block, meeting ASTM C-90 specs

- Use anchor or concrete expansion

- Stay away from mortar joints

- Keep at least 1” from edges

- Do not use hammer drill to avoid blowout inside of bloc

Hardware for brick

- Test brick integrity first: brick walls may be porous, brittle, etc.

- Use only recommended anchor from manufacturer

- Use wall plate or backer plate when possible